Better Lithium Ion

The New Energy Era Demands the Best Lithium-Ion Battery Recycling Solution

While the shift to electrifying cars is imperative for the planet, this transition will create a new environmental challenge without metals recycling innovations that are clean and cost-efficient.

140m electric cars globally by 2030 will create massive demand for lithium-ion batteries and critical minerals.

More than 6.5 million tons of lithium-ion batteries from EV are expected to be available for recycling 2025-2030.

Demand for lithium-ion battery materials in the next decade is predicted to increase over 575% for lithium and 1237% for nickel.

Mining for raw materials alone is insufficient to meet our lithium-ion battery needs and power a clean energy future.

Recycling is the only solution for keeping strategically critical metals within regional supply chains, reducing the dependency risk and environmental cost of relying on foreign sources.

AQUA METALS SOLVES THE MASSIVE LITHIUM-ION RECYCLING CHALLENGE

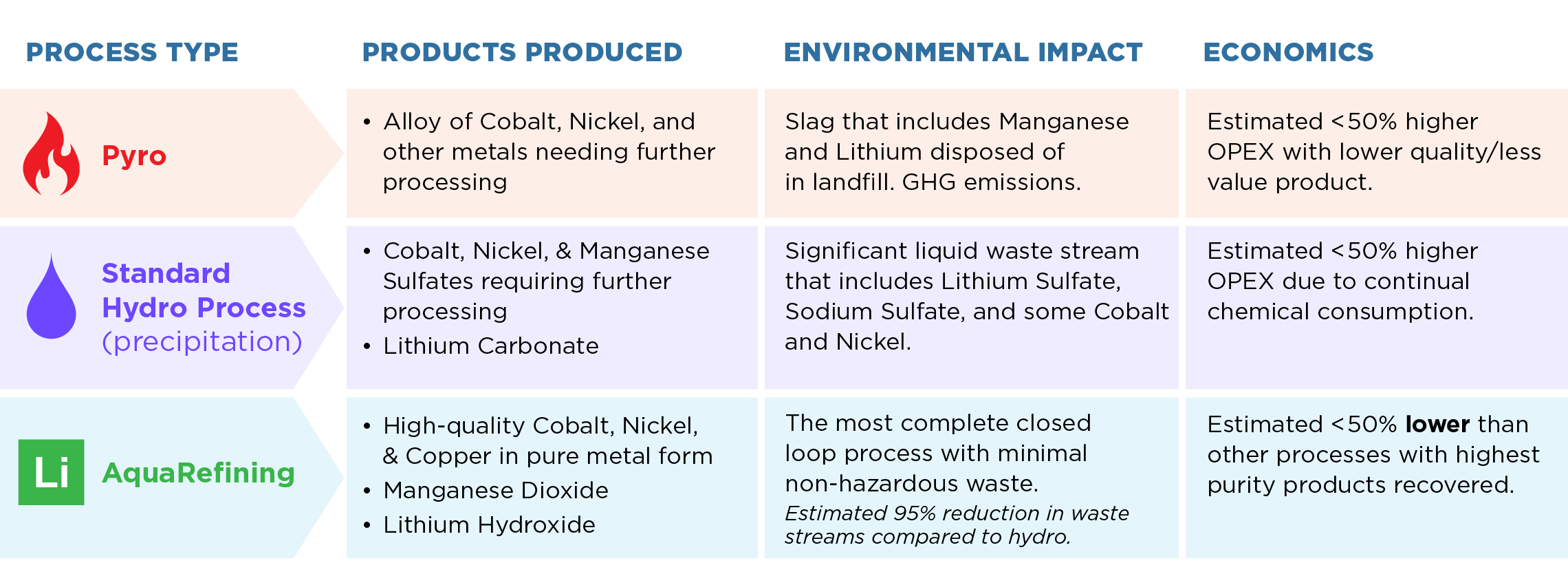

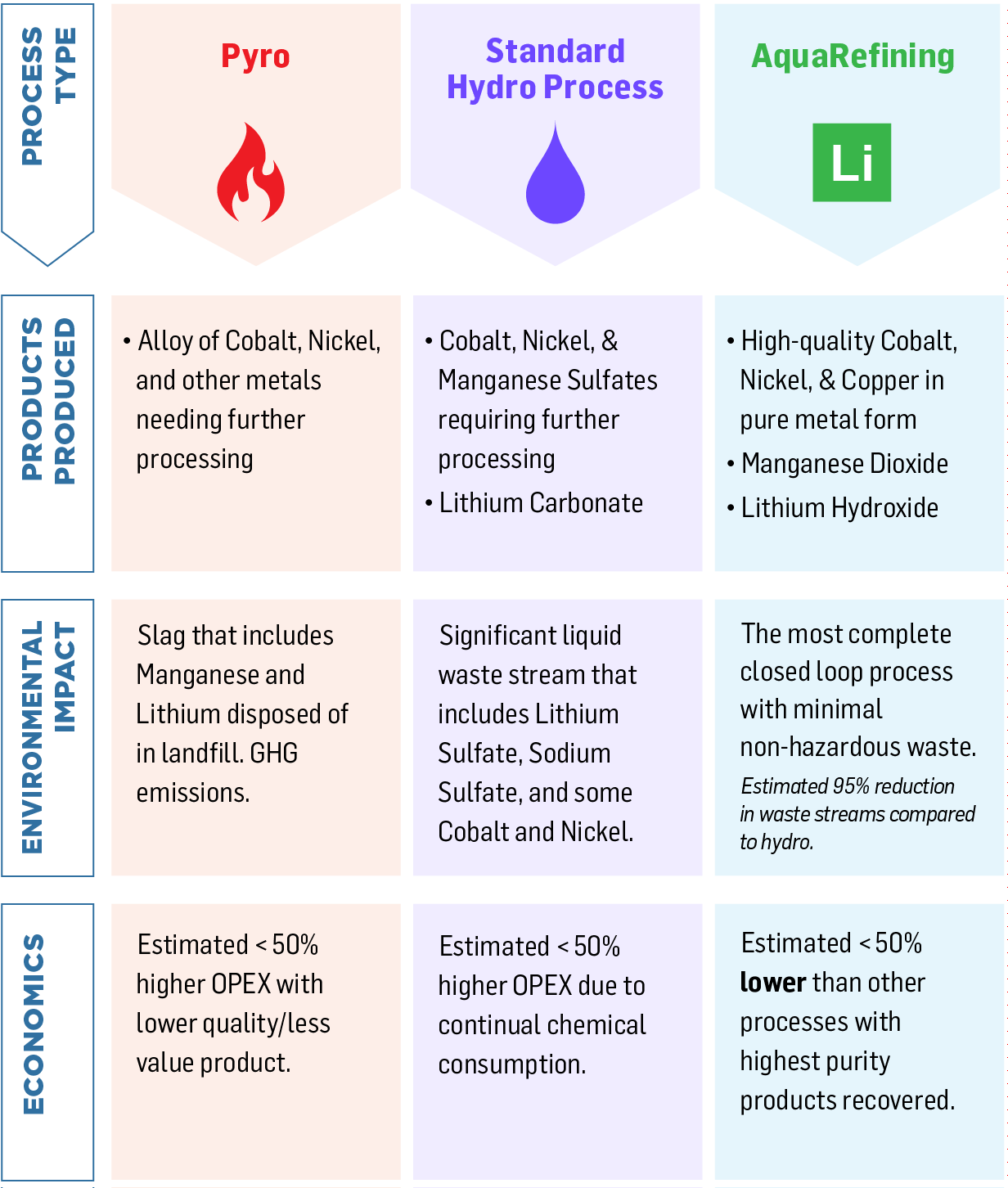

How our approach is different from other recycling solutions:

NO SMELTING

No furnace required, no greenhouse emissions

HIGHER %

Recovers a higher percentage

of metals in a higher

quality form

MINIMAL WASTE

Closed-loop process that

recycles chemicals

and water

HIGHER QUALITY

Produces higher quality

products at a lower

operating cost

AquaRefining, the cleanest approach to lithium-ion recycling, will produce a higher quality product at a lower cost.

THE AQUAREFINING ADVANTAGE

Aqua Metals’ Eco-Network

We believe a collaboration strategy with innovative companies that have multi-disciplinary backgrounds in metals, mining, high volume throughput, and hydrometallurgy is the best approach to solving the sustainability challenge of metals recycling, especially with lithium-ion batteries. Forming an eco-network is an important step in our strategy for exploring the expansion of AquaRefining technology to other applications.