As 2024 comes to a close, Aqua Metals is proud to share our recent achievements in advancing the future of sustainable lithium battery recycling. This year has been pivotal for us as we’ve continued to validate our innovative AquaRefining™ technology, strengthen our financial position, and work toward scaling up operations at the Sierra ARC facility.

Operational Breakthroughs: Pioneering the Circular Economy

At the heart of Aqua Metals’ mission is our groundbreaking Li AquaRefining™ process, which enables sustainable and cost-effective recycling of critical battery metals. This December, we reached a significant milestone with the successful completion of our first multi-week, 24/7 continuous pilot facility campaign.

The results are nothing short of remarkable:

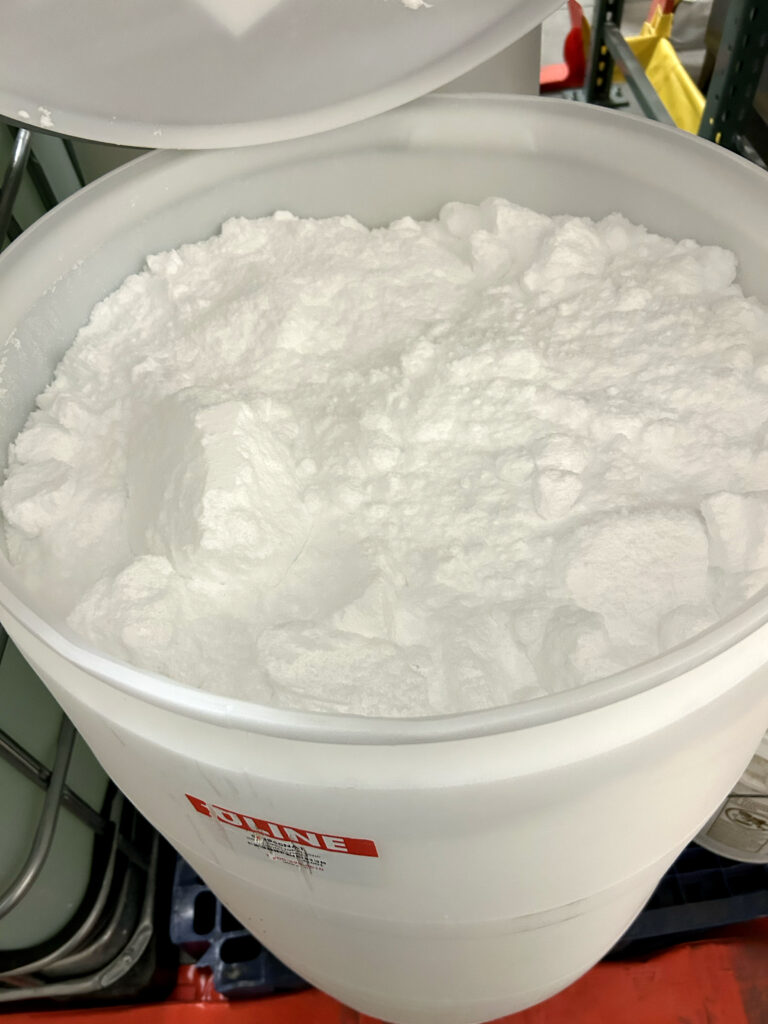

- Battery-Grade Lithium Carbonate: Over 600 pounds of lithium carbonate, produced meeting industry standards – further validating the performance of Li AquaRefining.

- High-Purity Nickel and Cobalt: Aqua Metals engineers produced 96.5% pure nickel and industry-standard cobalt rounds, critical components for the battery supply chain. Our patented technology is designed to produce battery-grade materials at a commercial scale.

- Outstanding Recovery Rates: We achieved over 99% recovery rates for lithium, cobalt, and nickel using our proprietary leaching process with 100% recycled solvents—eliminating waste streams like sodium sulfate and setting a new industry benchmark.

These milestones validate the scalability and efficiency of our process while positioning Aqua Metals as a leading player in the US circular battery economy.

Strengthening for the Future

To ensure continued momentum, Aqua Metals secured a $1.5M bridge loan, with over half funded by our leadership and Board of Directors—a testament to their confidence in our long-term vision.

This financing supports ongoing due diligence and strategic initiatives to secure transformative funding for our Sierra ARC facility, which is poised to lead the nation in sustainable, low-cost battery recycling at scale.

Looking Ahead: Building a Sustainable Battery Supply Chain

As we prepare for 2025, our focus remains on delivering U.S.-produced, sustainably recycled battery materials. With the Sierra ARC ready for equipment installation, we are finalizing long-term financing and advancing key commercial agreements for feedstock supply and product offtake.

This year’s achievements are a powerful reminder of Aqua Metals’ ability to innovate and adapt while remaining committed to our core values of sustainability and transformative recycling technology. We are excited to continue building the infrastructure necessary for a truly circular economy in battery recycling, powering the US battery sector, and enabling the clean energy transition.

Thank You and Onward

To all of our partners, investors, and supporters, thank you for being part of our journey in 2024. Your belief in our mission is what drives us to achieve more every day. Stay tuned for more updates in early 2025 as we continue advancing toward a cleaner, greener future.

Let’s keep pushing boundaries together.

*For more details on our latest progress, read our latest press releases here: https://ir.aquametals.com/press-releases